Non-silicone release agents are products applied to the backing of adhesive tapes to prevent unwanted sticking.

PEELOIL® is a non-silicone release agent with a wide range of applications.

| PEELOIL® (Non-silicone) |

Silicon-based Counterparts | |

|---|---|---|

| Advantages |

◎ No migration to adhesive surface ○ Overlapping tapes stick to each other ○ Can be printed and written on ○ Low-temperature processability |

○ Smooth peeling and controllable release ○ High heat and solvent resistance |

| Disadvantages |

× Poor heat and solvent resistance × Peel force is difficult to control |

△ Migration to adhesive surface × Overlapping tapes don't stick together. × Requires high-temperature curing |

PEELOIL® offers several advantages over its silicone-based counterparts, including low temperature processability, stick-slip behavior, and printability.

Non-silicone release agent

Silicone-free and suitable for various industrial applications

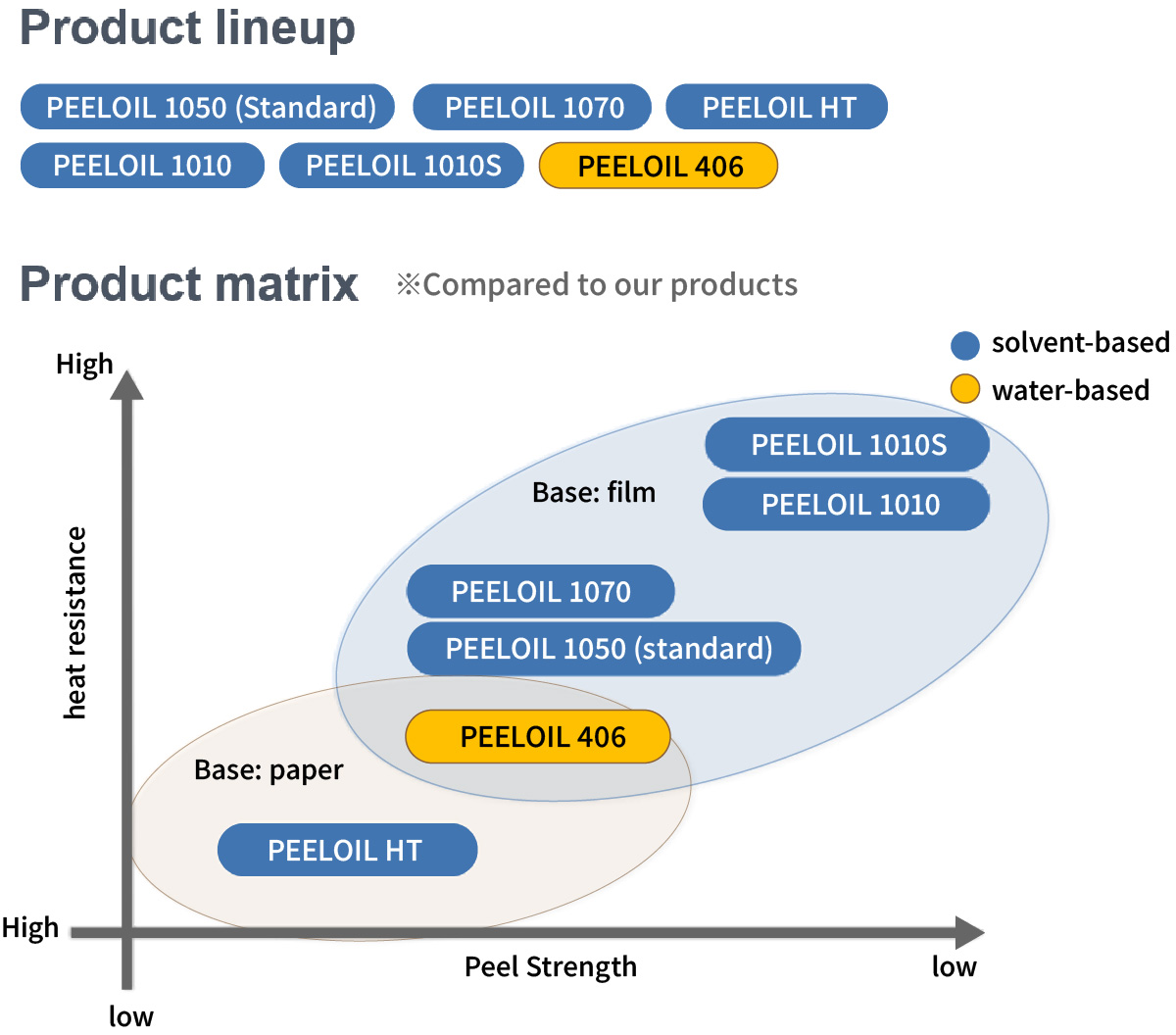

Solvent-and water-based variations

Choices available depending on intended use

Selectable heat resistance and peel strength

Choices available to suit environmental conditions and intended use

Compatible with various substrates

Compatible with such materials as film and paper

Packing tape

Masking tape

Sticky notes

Curing tape

Protective tape

LCD Protective film tape

1

Prepare the solution at the specified concentration

Mix the release agent with a solvent (e.g., toluene) to achieve the appropriate concentration.

2

Heating treatment (only for PEELOIL 1010 and 1010S)

Heat at a temperature between 40 and 50℃.

3

Application to substrate

Use a gravure coater or similar equipment to apply the release agent evenly onto film or paper.

4

Drying and solvent removal

Use hot air ranging from 80 to 100℃ to dry the substrate and remove the solvent.

| Product name | Application | Characteristics | Effective ingredient (%) |

Melting Point (℃) |

Solubility | Features | How to use | ||

|---|---|---|---|---|---|---|---|---|---|

| Appearance | Composition | Solvent | |||||||

| PEELOIL 1010 | For film | Pale yellow solid | Long-chain alkyl pendant polymers | — | 90 | 85 | Dissolves in thermal toluene | Backside treatment of various types of tapes Light peeling strength, good heat resistance No migration to adhesive surface |

0.05-0.1g/m2(dry) application (Liquid heat retention is required during coating) |

| PEELOIL 1010S | For film | Pale yellow solid | Long-chain alkyl pendant polymers | — | 98 | 85 | Dissolves in thermal toluene Water insoluble |

Backside treatment of various types of tapes Light peeling strength, good heat resistance No migration to adhesive surface |

0.05-0.1g/m2(dry) application (Liquid heat retention is required during coating) |

| PEELOIL 1050 | For film | Pale yellow liquid | Long-chain alkyl pendant polymers | Toluene methanol | 10 | 55 | Toluene dilution possible | Backside treatment of various types of tapes Easy to coat Liquid type of PEELOIL 1010 series |

0.05-0.1g/m2(dry) application |

| PEELOIL 1070 | For film | Pale yellow liquid | Long-chain alkyl pendant polymers | Toluene methanol | 5 | 65 | Toluene dilution possible | Heat-resistant improved type of PEELOIL 1050 | 0.05-0.1g/m2(dry) application |

| PEELOIL HT | For Japanese paper, general paper and cloth | Pale yellow liquid | Alkyl acrylate Ester copolymer |

Toluene ethyl acetate | 18 | 40 | Readily soluble in toluene and ethyl acetate | Good overlap adhesion, paintability and printability Suitable for backside treatment of masking tape, cloth tape, etc. |

1-3g/m2(dry) application |

| PEELOIL 406 <emulsion type> |

For film | Milky white liquid | Long-chain alkyl pendant polymers | Emulsion type | 15 | 70 | Water soluble | Backside treatment of various types of tapes Emulsion type of PEELOIL 1010 series |

0.05-0.2g/m2(dry) application |

INDONESIA

PT. IPPOSHA INDONESIA

Jl. Inspeksi Cakung Drain Timur No.1 Jakarta Timur 13910 Indonesia

CHINA

Under maintenance

INDIA

Under maintenance

JAPAN

LION SPECIALTY CHEMICALS CO., LTD.

〒111-8644

1-3-28 Kuramae, Taito-ku, Tokyo