Mandrel Release Agents

Introduction

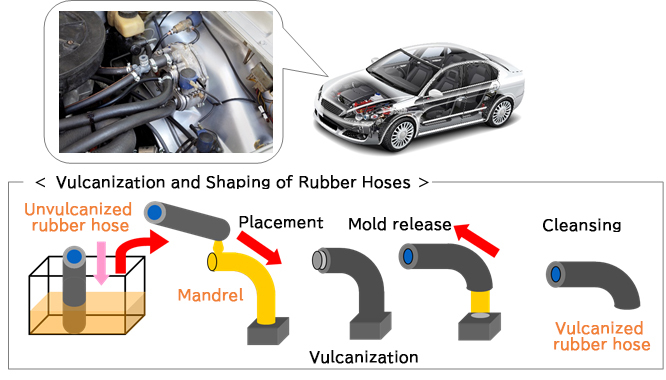

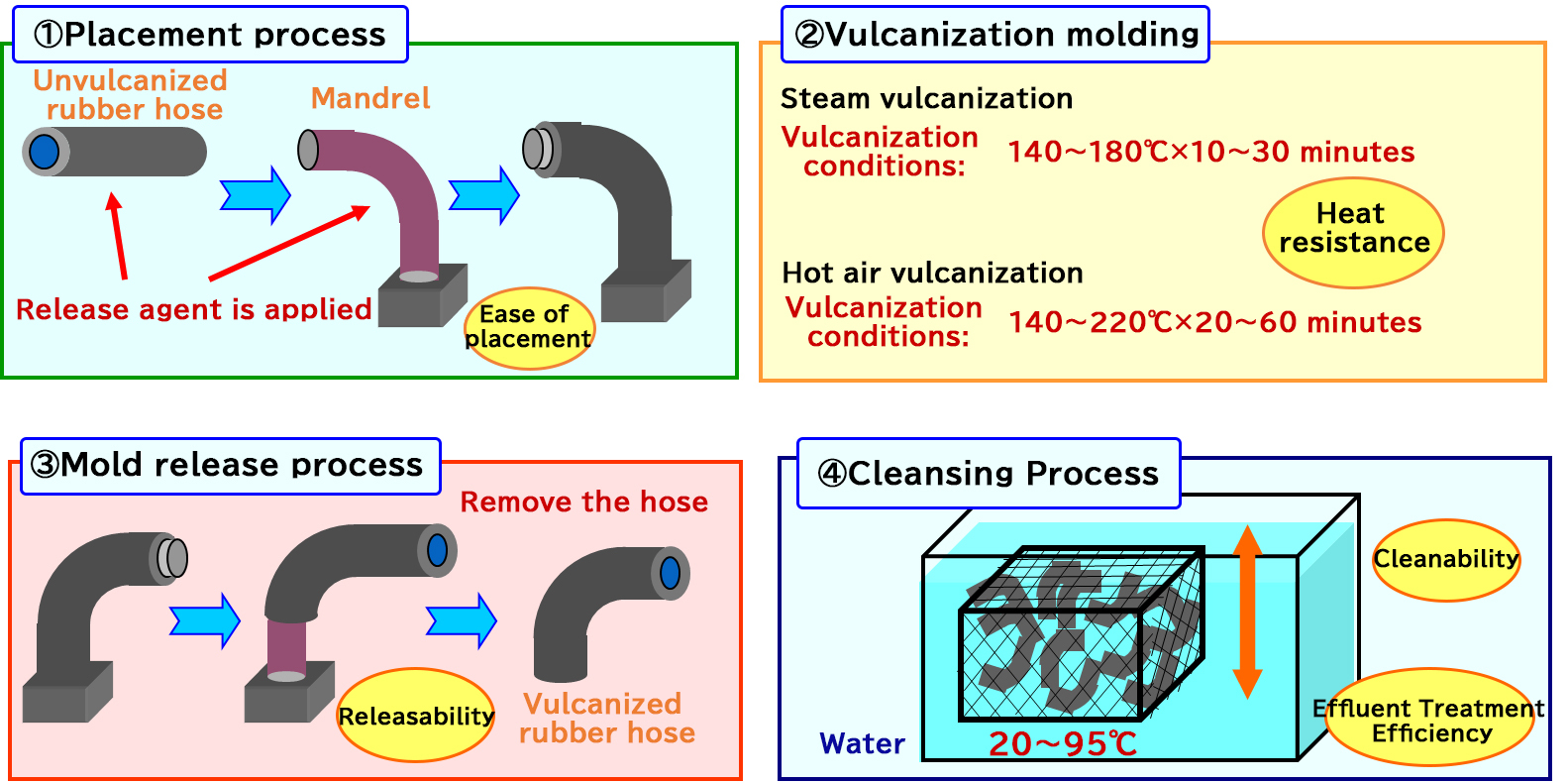

Various types of rubber hoses are used in automobiles. During the production of curved hoses, mold release agents are employed to prevent the adhesion of the rubber and mandrels. For hydrophobic rubber surfaces, these mold release agents utilize such technologically advanced component materials as nonionic surfactants to ensure excellent ease of placement, releasability and cleanability.

Mandrel Release Agent Performance Requirements

Key Factors Affecting Ease of Placement and Mold Releasability

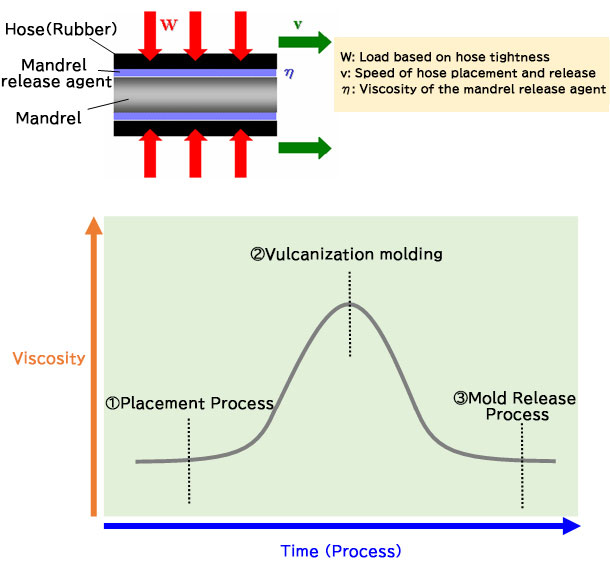

In terms of ease of placement and mold releasability, the viscosity/temperature of the mandrel release agent plays a crucial role. The ideal viscosity allowing for both easy placement on and release from the mold varies with hose shape and size, as well as temperature during the vulcanization process. We offer various grades tailored to load, speed of placement on and release from the mold, and temperature during the vulcanization process.

Behavior of Mandrel Release Agent with Ideal Viscosity (Conceptual Diagram)

| 1. Placement Process | The appropriate viscosity balances application to the hose and ease of placement. |

| 2. Vulcanization Molding | As the temperature of the hose rises, the viscosity of the mandrel release agent increases, which prevents the release agent from flowing out and suppressing the formation of gaps between the hose and the mandrel. |

| 3. Mold Release Process | As the temperature of the hose decreases, the viscosity of the mandrel release agent appropriately decreases, making it easier to remove the hose. |

References

竹内 俊哉 防着剤などのゴム用添加剤

(一社)日本ゴム協会関西支部 9月例会講演会、Web講演会、2020年10月22日