Back Release Agents

Molecular Orientation and Peel force of Alkyl Pendant Polymer Films

1. Technical Features

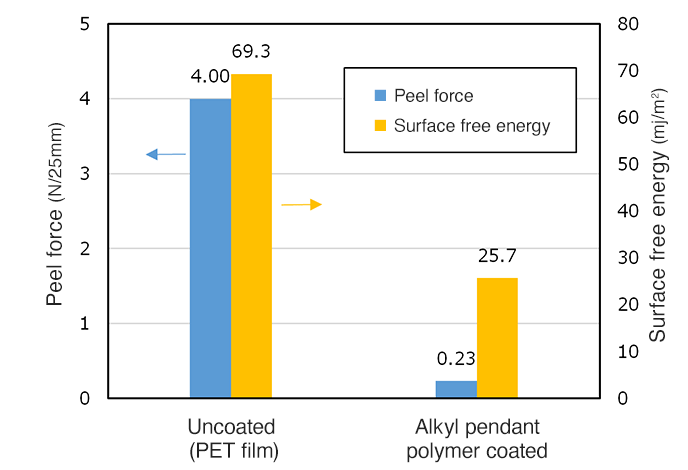

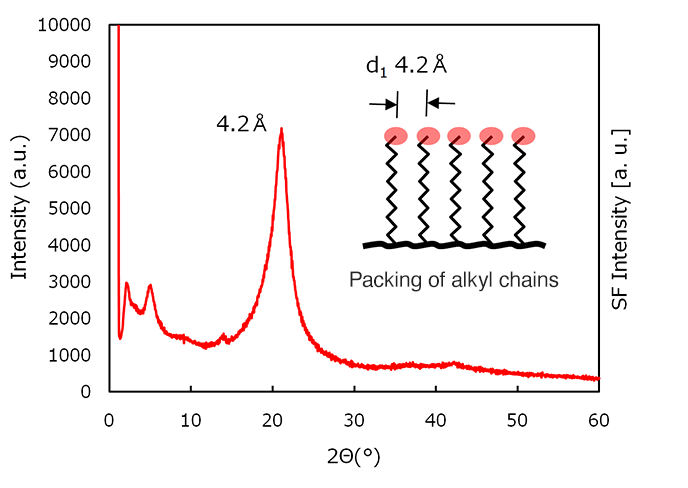

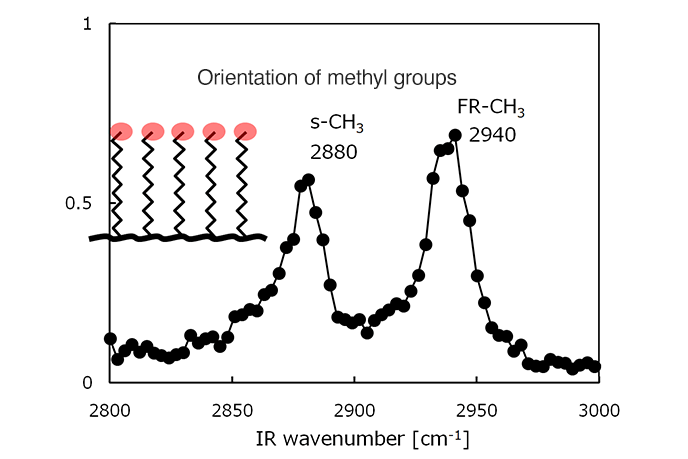

Alkyl pendant polymers are primarily utilized to coat the reverse of adhesive tapes used in various fields, including packaging. This polymer film is a necessary component for tapes because it makes removal from the roll easier and lowers adhesive strength without impairing adhesive performance (see Fig. 1). Because of the packing of the alkyl side chains (see Fig. 2) and the orientation of the methyl groups on the top surface (see Fig. 3), alkyl pendant polymers can readily produce low surface free energy films by applying the solution and letting it dry.

Fig. 1 Peel force and free surface energy

Fig. 2 XRD analysis of polymer film

Fig. 3 SFG spectra of polymer films

2.Performance Features

Alkyl pendant polymers have good layering and writing qualities (such as in oil-based pens) and are easily able to impart release properties to paper and film, which makes them ideal as release agents for packaging tapes (see Table 1).

| Alkyl pendant polymers | Silicone-based | |

|---|---|---|

| Peelability | ○ | ◎ |

| Printability, Writing | ○ | △-× |

| Overlap adhesion | ○ | △ |

| Thermal cure | Not necessary | Necessary |

References

- 川上, 「アルキルペンダント型ポリマー膜の分子配向と剥離力の相関」, 第63回高分子討論会

- Fumiya Mori et al: International Journal of Adhesion and Adhesives, 82, 166-172 (2018)